It was a warm May weekend in a basement electrical vault on the ГЫМТґ«ГЅ Halifax campus. It was even warmer for anyone wearing a 40-pound arc flash suit, its heavy, flame-resistant layers designed to protect electricians from the blast of an electrical fault that could reach temperatures hotter than the surface of the sun.

The bulky gear, complete with insulated gloves and a tinted face shield, is required whenever electricians work near live high-voltage equipment — like the kind at the centre of weekend-long planned power shutdown on both Studley and Carleton campuses.

“The suit is hot and the anxiety is through the roof,” says ГЫМТґ«ГЅ electrician Gillis Batherson, who along with his colleague Brandon Sanford had the suit on and off dozens of times during the weekend. “Electricity can do weird things. I kiss my kids goodbye a little longer on the days we have a shutdown like this.”

This May and on multiple other occasions, Batherson and Sandford have been joined by more than 125 other Dal staff, contractors, security and others who work together to upgrade the university’s electrical infrastructure at a time least disruptive to campus teaching and research activities.

Electricity can do weird things. I kiss my kids goodbye a little longer on the days we have a shutdown like this.

“Our electrical infrastructure basically is equivalent to what is needed to power a housing subdivision,” says Craig Arthur, Dal's assistant vice-president of Facilities Management. “Only it is much more complicated because of the variety and age of the buildings on these two campuses, as well as the critical research systems we have.

“We know how inconvenient it is when we have to turn the power off but it really is short term pain. The work we do during these shutdowns, in partnership with Nova Scotia Power, is to complete critical upgrades that will help us secure our power supply in the decades to come.”

One point of entry

The heart of ГЫМТґ«ГЅвЂ™s electrical infrastructure is a vault in the basement of the Weldon Law building. Back in 1970, ГЫМТґ«ГЅ was anticipating a lot of growth and built infrastructure to support future expansion. Three lines connect almost all the buildings on Carleton and Studley campus to that central vault — via cables that are so wide, they can barely fit in the palm of your hand.

Since 1970, campus has grown even more and technology has changed, which is why in 2015 ГЫМТґ«ГЅ began a massive project to update all electrical infrastructure.

“The equipment in the vault had to be replaced but so did equipment in each building,” explains Facilities Management’s electrical planner Darryl Babin. “Logistically it would not be possible to upgrade all the equipment in all the buildings during one shutdown, so we had to break the work into a series of events to be less disruptive to campus activities.”

In December 2024, the project team took advantage of the holiday break to arrange for the delivery of a new 25kV capacitor bank and new 25kV switchgear. The street had to be blocked off so that a large crane could lower the equipment, section by section, into the vault access shaft. This access shaft is concealed by concrete blocks that rest on steel beams and are further protected by two large concrete pads. Each pad is larger and heavier than a midsize sedan.

The backup plan

Collectively over the span of this project, FM staff have given up thousands of hours of time away from families — during evenings and weekends, in the summer, and during university breaks — so that campus activities are disrupted as little as possible. Staff work with researchers months in advance to determine backup power needs to ensure critical research can continue during the shutdowns.

“It’s a massive amount of co-ordination,” says project manager Charles Bennett. “The last thing we want is for any sensitive research to be jeopardized in any way. We hold regular meetings in the months leading up to the planned shutdown to ensure every single researcher has what they need to protect their work.”

During last month's shutdown, there were 21 generators running on campus from Saturday morning, May 17, until Monday night, May 19. There were four crews working around the clock to keep the generators fueled and working well. While some buildings have full emergency back up, others have none and temporary generators are brought in.

Most of the residences can remain open as usual during shutdowns because of their built-in generators but the rest of the campus is closed to the general public for safety reasons. Important research buildings like the Dunn, LSC, SOSB and the Tupper remain open to limited personnel so researchers can come and go as necessary during shutdowns if there are critical items that need to be overseen.

The biggest challenge during any shutdown is the Chemistry building, one of the iconic Georgian structures facing Studley quad and built in 1912. Electricity must be maintained not only to protect research, but to maintain ventilation and items such as storage refrigerators given the chemicals stored in the labs.

Extra generators were also brought in to protect food services in the Student Union Building, and to maintain one of ГЫМТґ«ГЅвЂ™s most unusual assets — the Dalplex inflatable roof, which when opened in 1979 was the first of its kind in the world.

“The roof of the Dalplex is like a pressurized metal dome, and needs uninterrupted electricity to remain inflated,” says Arthur. “There is an existing backup generator but to be sure for planned outages, we sometimes bring a second generator onsite in case it fails.”

Generator outside Dalplex to ensure the stability of the inflatable roof during the planned power outage.

Some buildings are closed for the shutdown with no backup power at all except for emergency lighting and alarms. This includes older buildings like Forrest, Burbridge, Hicks, Chase, and Studley, along with new ones like Weldon, the Arts Centre, Ken Rowe and the Goldberg Computer Science Building. Security is constantly on rounds keeping all buildings closed for safety, as no power also means no fire alarms or ventilation.

Getting down to business

With generators in place, and campus emptied, it was time to start the process to shut the power off.

Electrical supervisor Ryan Pietarinen, an electrician by trade, is at command central.

“We had four crews, and it was like a shotgun start at a golf tournament. One by one the crews would check in. The generators would be on and they would confirm that power was stable within the buildings.”

Back in the main vault, Brandon Sanford climbed into the arc flash suit to turn off the first of four main distribution lines running throughout campus.

“Of all the work we do on campus, high-voltage electrical systems are some of the most dangerous,” says Arthur. “Electricians often have to work in tight spaces, they may encounter old or poorly labeled wiring, making it harder to know exactly what they’re dealing with. ГЫМТґ«ГЅ has a strict safety regime around all our trades, but electrical work, switching procedures, and the safety protocols and training that go with high-voltage work is in its own league.”

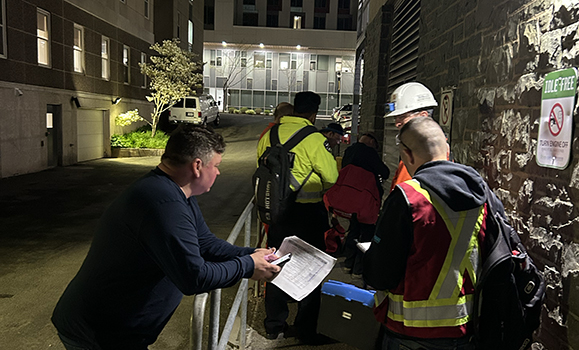

With the main lines were cut, the crew then hits the road and travels from building to building, taking the suit on and off as needed to de energize every building on the two campuses. The whole process took 3 hours.

Electrical crew travel from building to building turning the power off and on as needed.

Nova Scotia Power crews then began their portion of the work, replacing 40-year old equipment and reconfiguring cabling to power new 25kV switchgear which provides essential electrical protection unlike ГЫМТґ«ГЅ has had before. It will also help distribute power to future buildings and reduce the cost of electricity bills.

Specialized contractors installed cables between the existing and new equipment within the electrical vault in the Weldon Law Building and moved between buildings to modify their main transformers. They tested the transformers after the changes to ensure the voltage was correct within each building before the power was switched back on.

“It has to be done in a sequence,” says planner Darryl Babin. “Restoring power requires each contractor to remove their locks from a lock box containing 50+ keys to help ensure the safety of everyone. We never want to see power restored without everyone knowing and equipment being sealed up safely.”

ГЫМТґ«ГЅвЂ™s electrical crew and contractors working on the main vault during the shutdown.

By midday Monday the work was done, and the crews started the long process to re-energize campus.

Once again, they went building by building switching on the power, turning off the generators, coiling up the lines and getting campus back to normal.

“I couldn’t be more proud of the team,” says Arthur. “This is an extraordinarily complicated process, which was done safely thanks to our professional staff who take every precaution. All departments of Facilities Management worked together — our trades staff, planners, project managers — together with our contractors and colleagues from all across campus, who work with us to prepare their individual departments and buildings.”

By the numbers

ГЫМТґ«ГЅ planned power shutdown — May 17-19, 2025

| Number of personnel | 150 |

| Hours of work for ГЫМТґ«ГЅ electricians | 309 |

| Number of generators | 21 |

| Amount of fuel for generators | 62,836 litres of diesel (cost: $89,000+) |

| Hours of work by security staff (Dal and external) to protect generators and lines, keep buildings clear, patrol campus, etc. | 1,027 |

| Number of accidents or injuries | 0 |

Left-to-right: Project Manager Charles Bennett, Electrical Planner Darryl Babin and Trades Supervisor Ryan Pietarinen.

ГЫМТґ«ГЅ staff involved in the shutdown

| Electricians | Other staff |

|---|---|

| Ian (Gillis) Batherson Jim Beaton Curtis Deacon Cameron Demers Brendan Doran Michael Hagedorn Michael Leblanc Sean Pomeroy Brandon Sanford David Shanks Jeffrey Snair Bradley Supple Drew Tavener Kevin Trueman |

Darryl Babin Charles Bennett Ryan Pietarinen Anton Hovorov James Wells Tim Jolly Tony Levy Troy Farnell Jason Roberts |